The HoverHandle Transforms a Hoverboard into A Fun, Easy to Ride and Control Transportation Device.

In addition to the pure entertainment value of a hoverboard, a new world of personal transportation devices is coming and many analysts believe that the hoverboard will thrive in the complex world of personal commuting. Our HoverHandle is the perfect tool for moving a hover board from Point A to Point B, from executives on Wall Street to students on campus, from warehouse employees to external delivery alternatives, the hoverboard and other personal transportation devices will soon engage our daily lives.

HoverHandle Gen 0

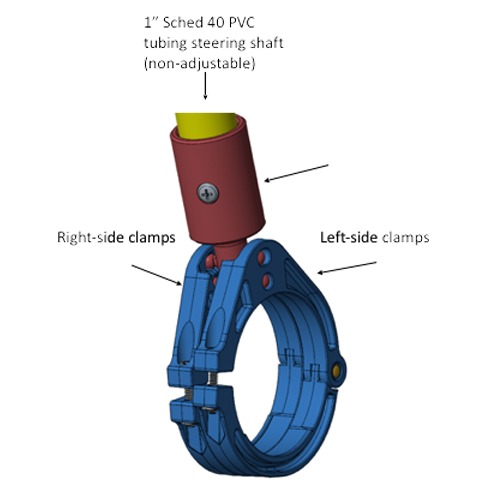

HoverHandle Gen 0  HoverHandle Gen 1

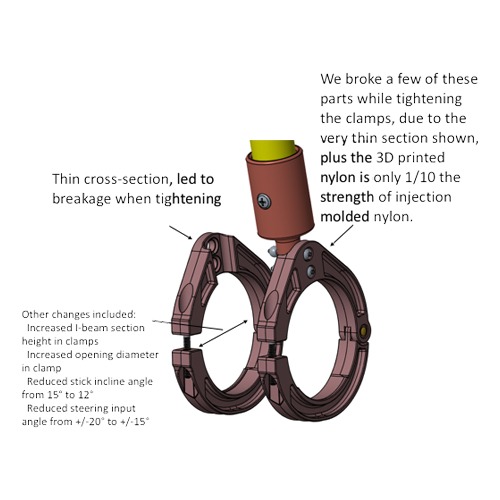

HoverHandle Gen 1  HoverHandle Gen 2

HoverHandle Gen 2